Anas Ma'ruf

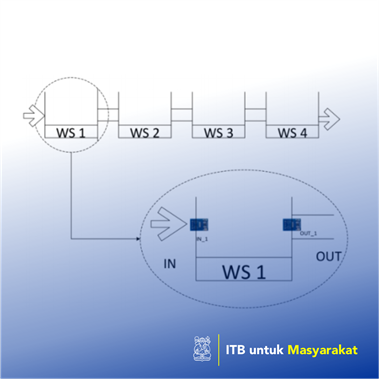

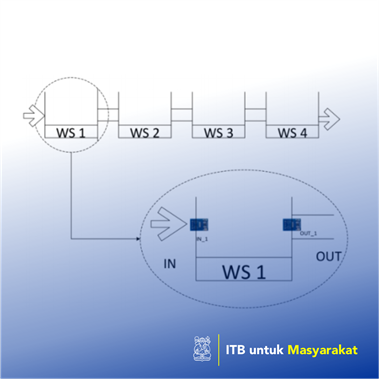

The previous sub-chapter model was tested using real system data. Time data can Judging in Appendix A and dependency diagrams can be seen in Appendix B. Amount operator is 30, the amount of ability level is 4, the number of tasks is 114, and ratio for products 1 worth 0.5; Products 2 to product 4 are 0.167. The data is included In the model and computing is done. The result of the computing is cycle time Proportional has a value of 3,3803 hours and assigned 28 operators from 30 operators. Time The computing used is 101 hours 43 minutes. This study proposes the operator assignment model on the product assembly trajectory mixture. Model characteristics can assign assembly activities in a team, where one Assembly elements can be done by more than one operator. Proposed final model is a linear model that is proven to be able to speed up computing time so it can Implemented to certain real systems.

Application of writing

This study develops the assembly operator assignment model for mixed products. The proposed model can carry out operator assignments in groups, where one Work elements can be done by more than one operator. Besides that, every element Work has a minimum requirement of operator skills that must be fulfilled. Selection Operators with higher ketriplang can shorten the assembly time. Model It has an objective function to minimize cycle time by considering the ratio Request each product and capability of each operator. The model was originally nonlinear which is then modified into linear and the number of variables is reduced for Computational time efficiency. numeric in the real system shows the feasibility of implementation The model for the number of assembly elements is quite large.