Asmudjo Jono Irianto

The pottery craft industry in Indonesia has stagnated in recent years. The centers of folk pottery production such as plered, Kasongan, Klampok, Ciruas and Bayat production do not increase, may even be said to decline. Outside Java, Lombok is one of the centers centers that two decades ago were very famous and most of his products were exported, the condition is very sad. One of the problems with folk pottery products is poor innovation, both in terms of techniques and design. At present almost most people's ceramic products use paint dyes if they are about to produce colored potpers. Glaze material (thin glass layer above the surface of the ceramic body) is too expensive for pottery craftsmen. With the furnace that the average fuel temperature is below 1000 0C, then the glaze that can be used by traditional craftsmen is low temperature glazers. The problem, low temperature glaze is expensive, because it uses lead (lead oxide) as a flux (reducer of kursa melting point). Besides being quite expensive, lead is also toxic and dangerous if used as a glaze on a dining and drinking container. In addition to lead there are several other materials that are effective as low temperature flux, such as soda ash and borax. Unfortunately the two ingredients dissolve in water so it is difficult to use as flux, because the application of glaze material to the surface of the ceramic generally uses water media. Because it dissolves in water, the composition of glaze that uses Sodah Ash and Borax is difficult to stable (partially borax and ash soda disappeared dissolving in water)

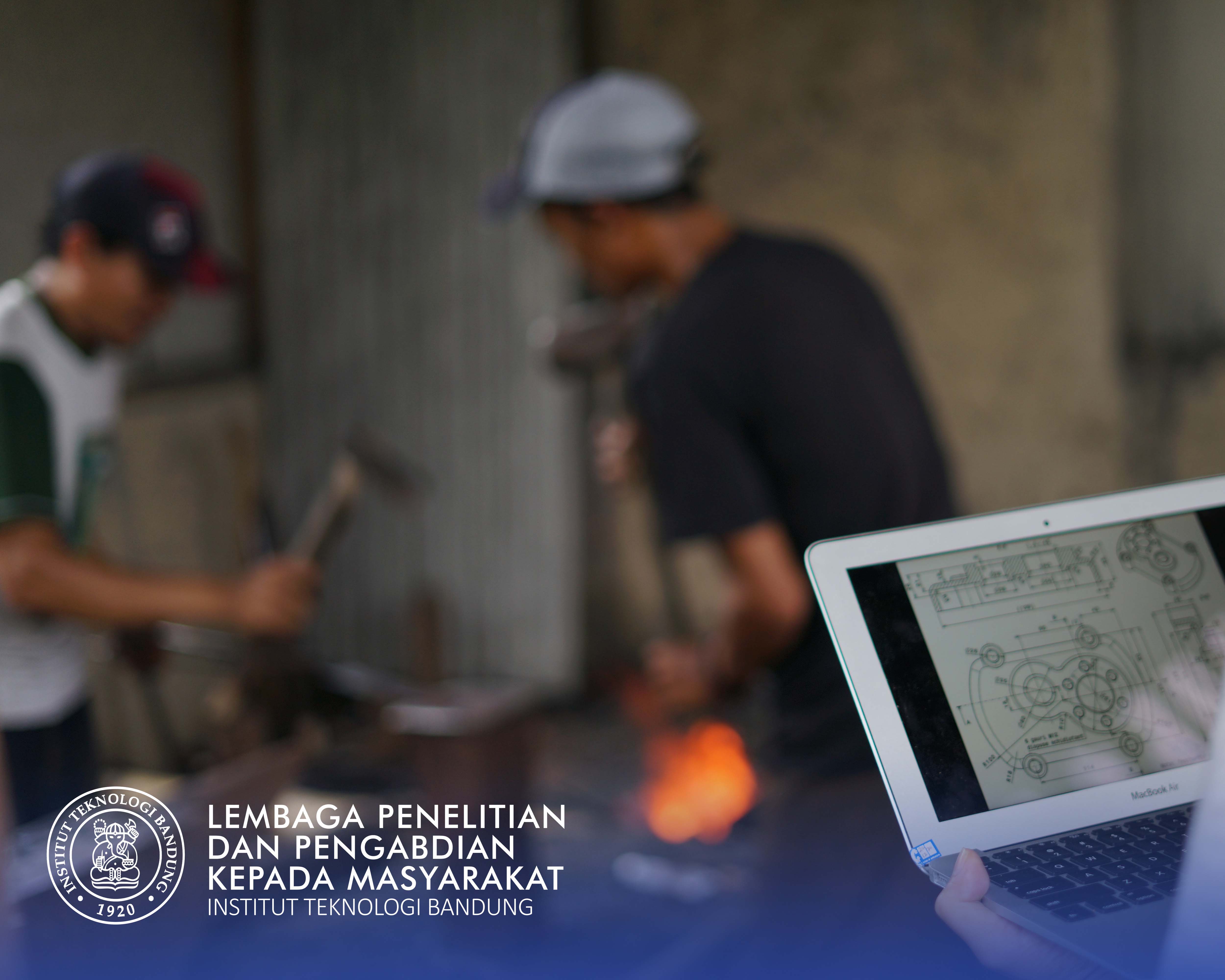

Application of appropriate technology to

One of the problems with folk pottery products is poor innovation, both in terms of engineering and design.