Bermawi Priyatna Iskandar

The remanufacturing process is a separate term that refers to the process making back a product to achieve original manufacturing product specifications By using the combination of product parts that are reused, part-part Repaired and the part-part is really new. Remanufacturing paradigm appears along With the development of the circular economic concept, where in economic utilization from a product as much as possible the product will be maintained As long as possible, the product is taken as much as possible, and then at the end of the life of the product and the supporting material will be used again in The next manufacturing process. This research will begin with the literature study to see research at The field of material planning that has been done by other researchers. Then Parallel will also be searched for companies in Indonesia that are right and move on the field of remanufacturing considering that there are not many companies in Indonesia that are engaged in The field. From the company it will be collected in corresponding data for the condition of the remanufacturing process, so it can be formulated that mathematical model describe the process. With the introduction of uncertainty factors on Material planning, the model made will be probabilistic or stochastic, so the settlement of the model is also expected to be through statistical techniques and Operations Research is corresponding to the condition of the model.

Application of writing

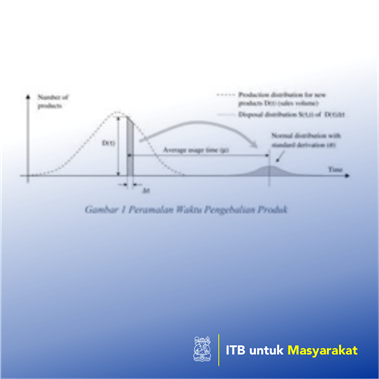

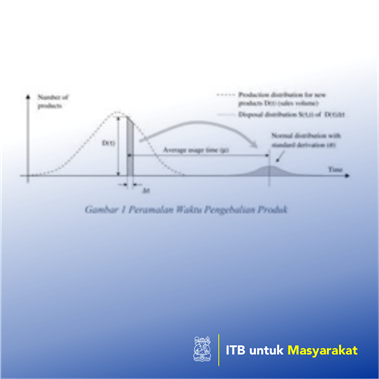

The remanufacturing paradigm application has different problems with practice Manufacturing which has been commonly carried out by manufacturing manufacturers. Main focus remanufacturing that emphasizes re-utilization of products that have expired the use requires that the manufacturer must have a good reverse logistic network to regain a product that has expired as a raw material main of remanufacturing products. In addition, there are also difficulties to plan When the main raw material can be available to begin the remanufacturing process. This matter caused by uncertainty when a product will be used by Other customers before the manufacturer can be retrieved. The explanation confirms that needed a different material needs planning method planning traditional material needs that have been used by the perpetrators Traditional manufacturing. The image below illustrates how time forecasting Returns of products can be done using an average data life product.